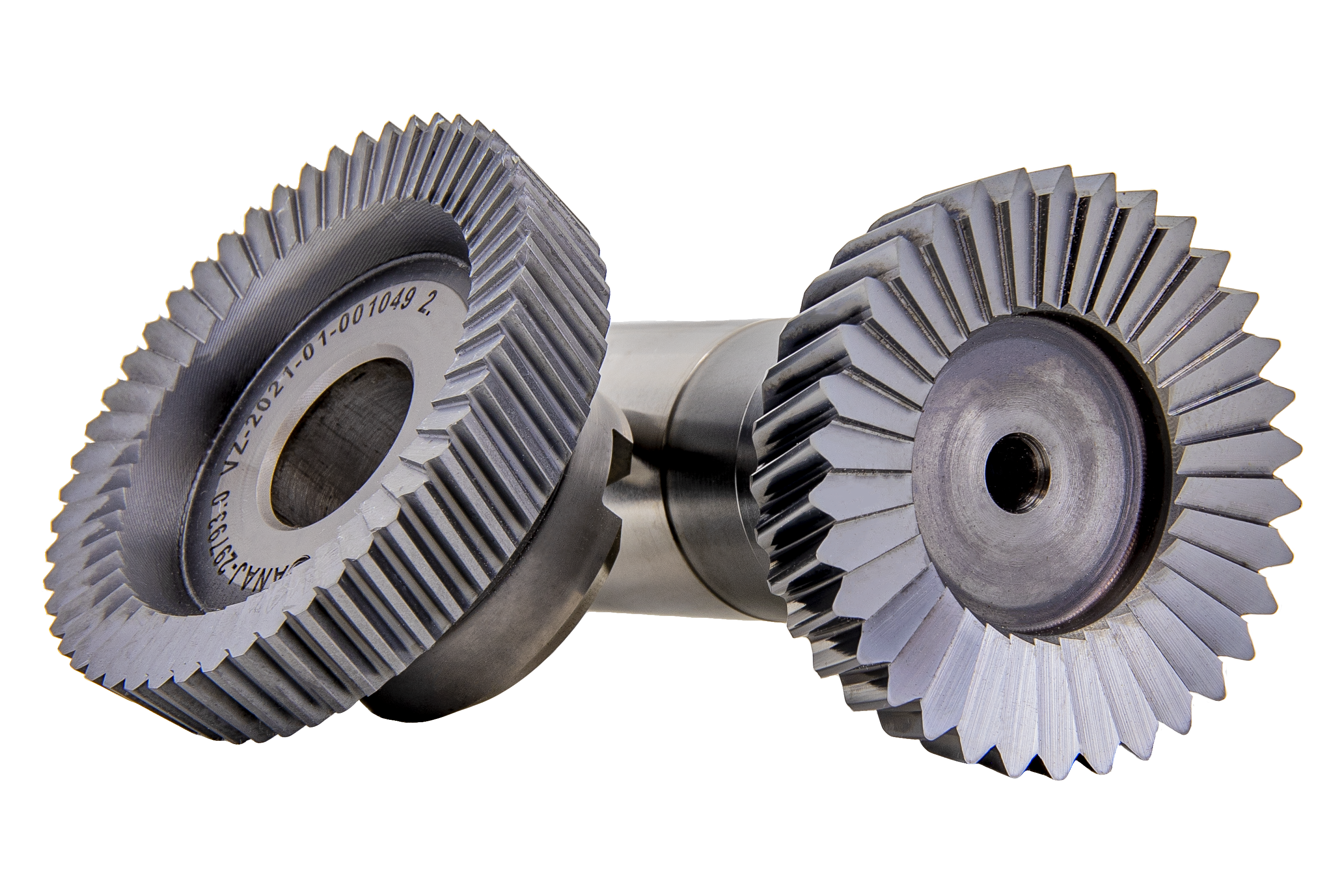

In the field of internal and external gearing, we specialize in the design and development of unique skiving tools. Our tools are manufactured from HSS, HSS PM, and HM materials, with a strong emphasis on durability and stability during machining. All tools are supplied with PVD coatings to ensure the high-quality machining of gears.

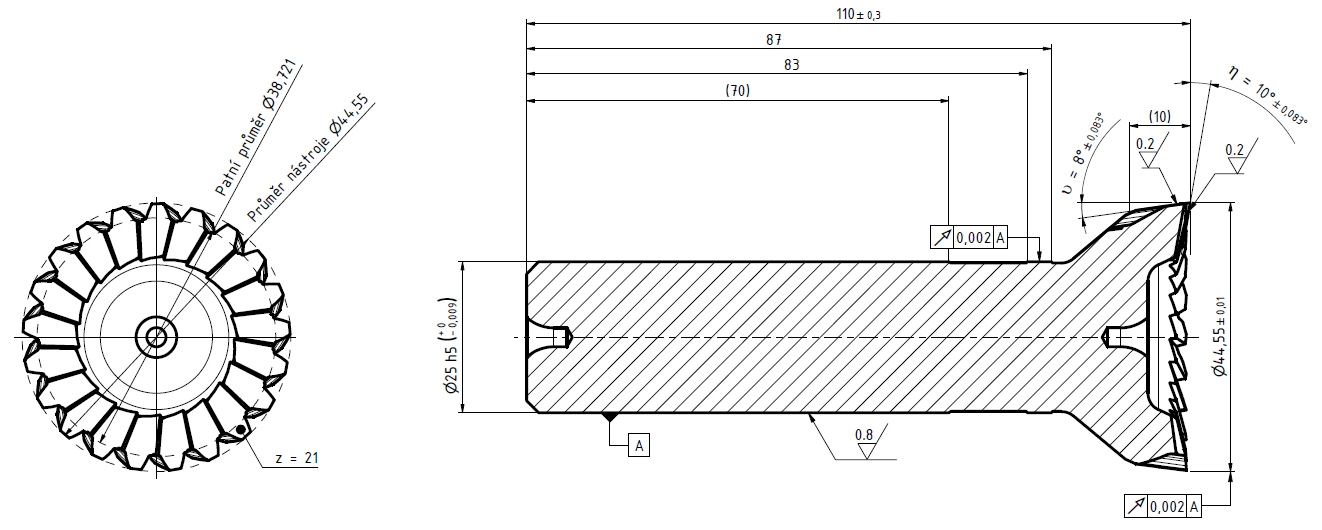

The development and design of our tools are based on customer-specified parameters, taking into account special profile requirements, including shape modifications. To ensure the highest tool standards, our team of experts conducts trajectory simulations for individual tool edge sections during skiving machining, as well as kinematic simulations during the grinding process of skiving tools. This results in excellent durability, profile stability, and sharp cutting edges. We utilize advanced ESCO software, along with 2D and 3D modeling tools from Autodesk, for the design and development process.

All tools undergo inspection and measurement on specialized equipment designed for profile and shape deviation checks (e.g., MAHR, WERH, ZOLLER, WALTER). Profile inspections comply with DIN 1829 standards or other customer-specific requirements.

Our experts, both in the field and in the design department, are available not only to initiate the production of new tools but also to assist in solving operational issues, evaluating tool profitability, lifespan, or the condition of your existing tools. We are ready to leverage our expertise to address your needs and requirements directly on-site.

We also provide sharpening services for the tools we manufacture as well as tools from other producers. Sharpening is performed with precision, maintaining the same level of quality as the original manufacturing or according to your specific requirements.