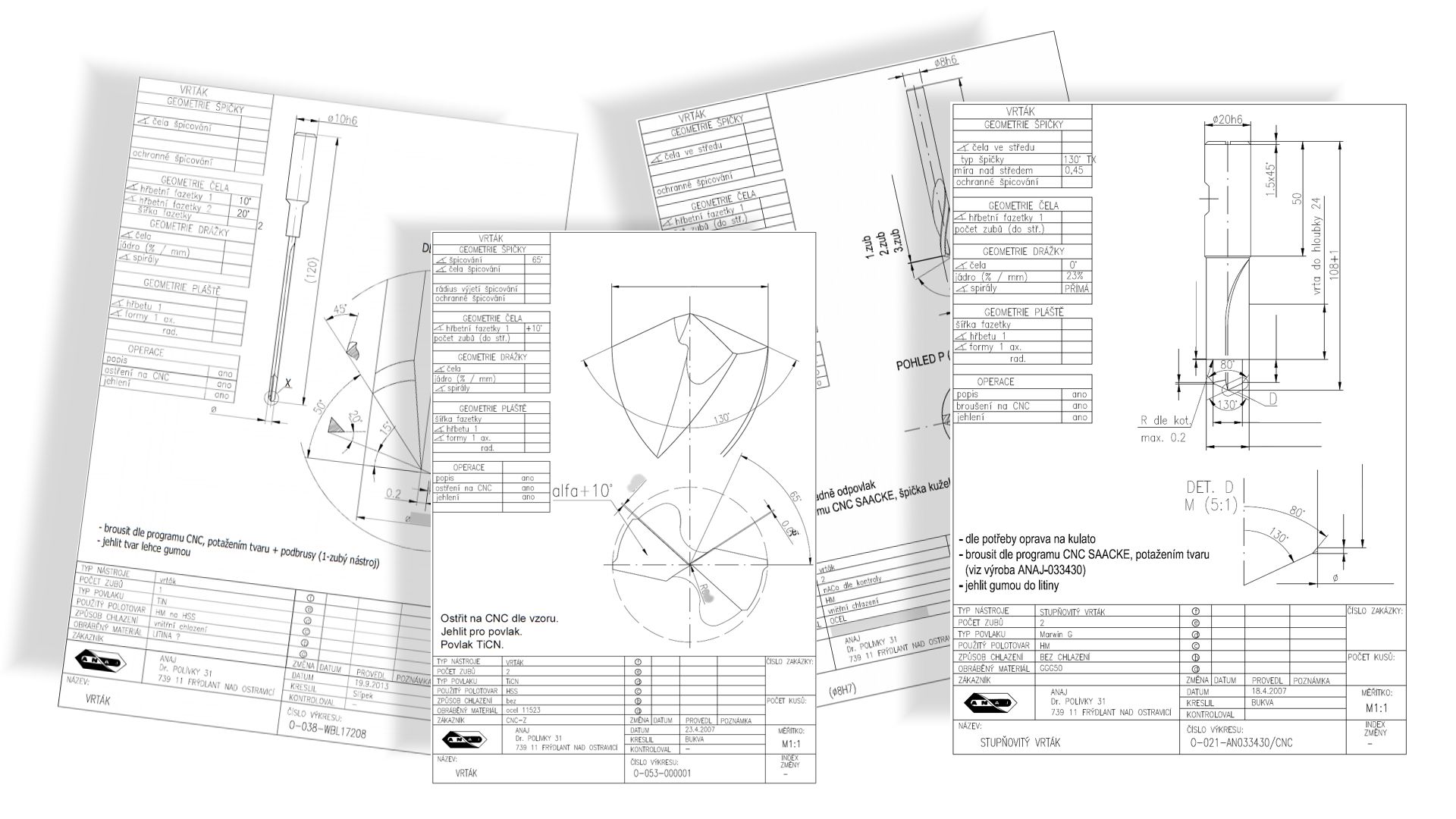

All the information needed to guarantee the correct cut and quality focus are transferred to the so-called. Sharpening drawing. It is tied with a sharpening tool through the code and contains detailed information on the required dimensions and geometries. On the basis of data focussing drawing is then created and CNC measurement programs, which are also linked through sharpening the code.

The first step in the process of sharpening specials are correct identification tool sharpening a unique code. It contains the customer code and a unique identifier tool. Then firing this laser marking tool popisovačkou minimize errors in all subsequent process steps sharpening.

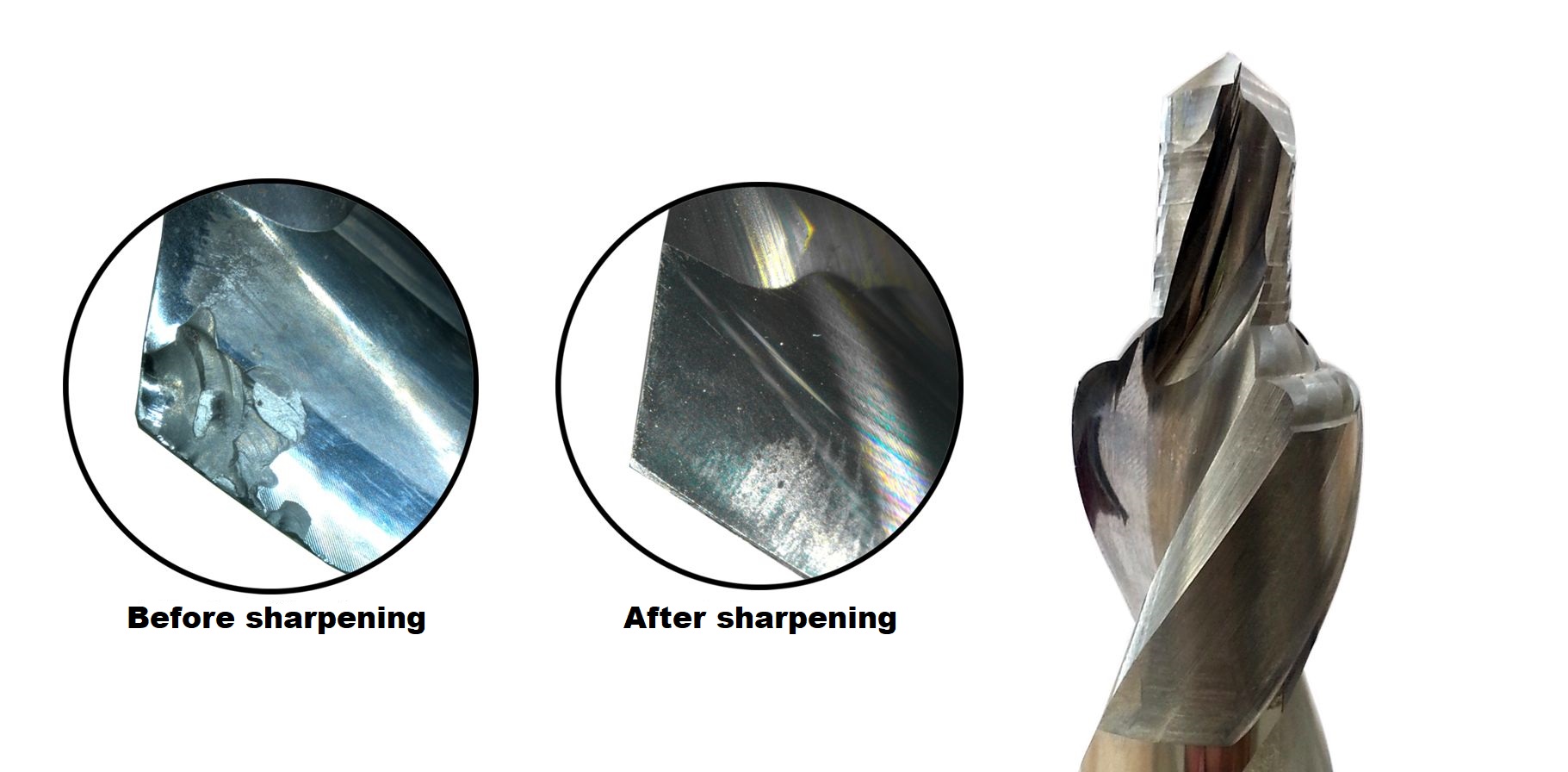

Sharpening grinder use reputable companies SAACKE, Deckel and ANCA. Regular maintenance and renewal of machinery along with experienced service guarantee customers the required accuracy and quality of cut.

In collaboration with outside vendors to apply tools of high quality PVD coatings. This gives a higher service life, increase the speed and resulting quality of machining.

Process and output control is performed on high-end measuring devices from companies and Walter Zoller. Every measurement is recorded and all information is archived. Output control is carried out with the agreement on a customer drawing is declared and protocol compliance.